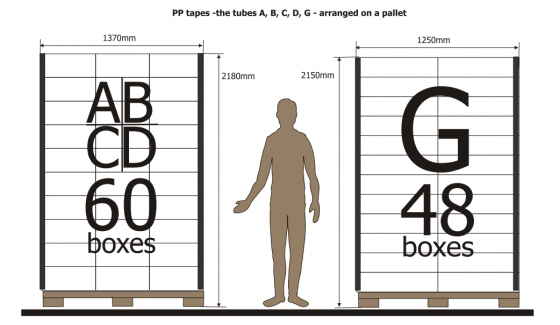

Strapmet is a company which has cooperated with Defalin Group S.A. for many years. Strapmet can offer optimal solutions in the field of products’ packaging. Knowledge, experience and constant improving their capabilities are the chief asset of the specialists’ team which allow the company to offer machines and accessories capable to fully satisfy needs of their customers. The company continously cooperate with leading manufacturers of the packaging machines and equipment so that they can constantly enlarge their offer. The offer of Strapmet includes: strapping machines, sealing machines, packaging tools, polyprophylenie and polyester tapes printed as well as printless,

ropes, twines and other packaging accessories.

|

AUTOMATIC and SEMI-AUTOMATIC PACKAGING MACHINES

Strapment company offer the automatic and semi-automatic packaging machines of the newest generation, featuring high working speed and operation easiness as well as finest quality of the strapping process. Utmost reliability of these machines is undeniable.

|

|

ACCESSORIES FOR PACKAGING

Sealing hand device fastens together the PP strapping tape’s ends by use of vibratory sealing. It does the work in a way typical for automatic devices (i.e.sealing, tightening and cutting). Inexpensive and reliable packaging of the goods is guaranteed despite small size of this device.

Tensioner for PP strapTensioner for PP strap is a simple metal device used for stapling together two ends of PP straps. It also provides tightening of the tape and automatic cutting off pieces of necessary lengths.

Special truck enables transportation of straps during the process of packaging and also protects the tape against unwinding and tangling up. It is a superb supplement to the sealing hand devices and tensioners for PP strap.

|

|

For more information on the packaging machines and accessories see Strapmet website.

DEFALIN GROUP S.A. can offer a possibility of delivery by a forwarding company.

DEFALIN GROUP S.A. can offer a possibility of delivery by a forwarding company.